The Importance of Using Plastic Plugs and Caps in Protecting Products During Transit

In a global marketplace that relies heavily on the safe transit of goods, protecting products is more critical than ever. Each stage of a product’s journey from manufacturer to end consumer poses potential hazards, from dust and moisture to physical impacts. Plastic plugs and caps play an integral role in shielding items from such dangers, preserving both the integrity of the merchandise and the manufacturer’s reputation. Understanding the full spectrum of benefits these simple components offer is essential for any business involved in product distribution. In this article, we’ll explore how they maintain product safety, enhance brand value, contribute to sustainability, and can be tailored to various sectors.

The Role of Plastic Plugs and Caps in Product Safety During Shipping

Goods shipped across different modes of transport are exposed to a vast array of potentially damaging elements. Plastic plugs and caps offer a first line of defense by sealing off components from invasive dirt, moisture, and contaminants. Items such as precision-engineered parts often have sensitive surfaces that could be compromised by exposure to the elements, making the protective attributes of these products indispensable.

By fitting snugly into openings or over protruding components, plastic plugs, and caps help in maintaining the structural integrity of a packaged item. This protective measure is especially crucial for products that undergo long-haul transport, where constant movement can mean an increased risk of internal and external damage.

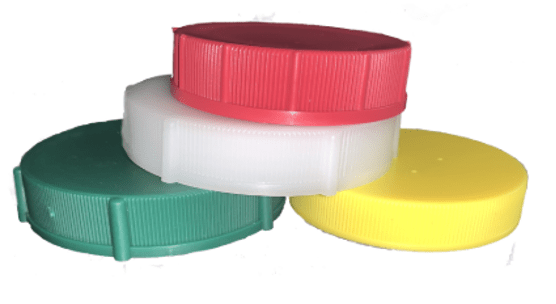

The versatility of plastic plugs and caps allows them to be utilized in a wide variety of applications, from electronic gadgets to heavy machinery. Each plug or cap is designed to provide a secure fit, ensuring that even if packages are jostled or overturned, the items inside remain free from damage and ready for immediate use upon arrival.

Enhancing Brand Reputation Through Secure Packaging Solutions

Companies today are judged not just on the quality of their products, but also on the care taken in delivering them to the consumer. Employing comprehensive protective measures with plastic plugs and caps reaffirms a company’s commitment to excellence, enhancing brand reputation through superior packaging.

Consumers often associate the condition of received goods with the values of the brand itself. When a product arrives without blemish due to the effective use of protective components, it reflects a brand’s dedication to customer satisfaction and attention to detail. In contrast, damaged goods can diminish trust and deter repeat business.

In competitive markets, word of mouth and customer reviews amplify the impact of both positive and negative experiences. The seemingly small act of securing products with plastic protection can lead to positive feedback and recommendations, leveraging customer satisfaction into tangible brand growth.

The Environmental Impact of Reusable Plastic Protection

Environmental considerations are now front and center in packaging decisions. Plastic plugs and caps offer a sustainable option as they are often reusable, reducing the carbon footprint associated with the production and disposal of single-use packaging materials.

By encouraging the use of reusable plastic protective components, businesses can demonstrate their commitment to sustainable practices. This commitment is increasingly valued by consumers, who are often willing to support brands that take clear steps to minimize environmental impact.

Moreover, many plastic protections are made from recyclable materials, further reinforcing a company’s green initiatives. Recycling plastic plugs and caps not only conserves resources but also reduces landfill waste, contributing to a circular economy where materials are continuously repurposed.

Customizing Plastic Protective Solutions for Various Industries

Plastic plugs and caps are not a one-size-fits-all solution. The diversity of goods being transported each day necessitates a range of customizable protective options tailored to specific industry needs. Manufacturers can design specialized covers that address unique shapes, pressure requirements, and temperature sensitivities.

From the pharmaceutical industry, with its demand for sterile caps that ensure the purity of medicinal products, to the automotive sector, which requires rugged plugs capable of withstanding significant mechanical stress, the applications are manifold. Such specificity in design confirms that every product can benefit from optimal protection.

Overall, the strategic use of plastic plugs and caps during transit offers undeniable benefits for business sustainability, customer satisfaction, brand reputation, and environmental stewardship. These simple yet critical components ensure that products arrive in the condition they left the factory, ready to meet or exceed the expectations of consumers, who are always just a ship away.

Keep an eye for more latest news & updates on Usa Tech Magazine!