Living Materials: How Bio-Fabrication is Enabling Self-Healing Products and Infrastructure

In recent years, the world has seen a rise in the importance of sustainability and innovation. One such breakthrough in this field is bio-fabrication. This process is changing the way we think about products and infrastructure. The fashion industry has also started embracing this technology. The Fashion Revolution has brought attention to the need for sustainable practices, and bio-fabrication offers one such solution. It enables the creation of living materials that can repair themselves, reducing waste and increasing the lifespan of products.

Bio-fabrication combines biology with manufacturing. This technique uses living organisms like bacteria, fungi, and algae to create materials. These materials can grow, repair themselves, and even adapt to their environment. This is a major step forward in creating sustainable and efficient products.

What is Bio-Fabrication?

Bio-fabrication is the use of biological processes to create materials and products. These materials are not just man-made but are alive. They can grow, heal, and evolve. Scientists use living organisms like bacteria and fungi to design and produce these materials. The materials they create are often stronger, more flexible, and more sustainable than traditional materials.

The main goal of bio-fabrication is to reduce waste. Instead of creating disposable products, bio-fabrication aims to create items that can repair themselves. This means that products will last longer, reducing the need for frequent replacements.

How Do Self-Healing Materials Work?

Self-healing materials work by mimicking biological processes found in nature. When a material is damaged, it can trigger a repair process. In biological systems, this process can happen automatically. For example, when skin is cut, it heals over time. Bio-fabricated materials work in a similar way.

These materials often contain living cells or microorganisms that respond to damage. When they detect a crack or break, they release compounds that help the material heal. This process can take place over time, just like how our bodies heal themselves.

In some cases, the materials are designed to react to environmental changes. For example, they may respond to temperature, humidity, or light. This ability to self-repair makes them incredibly useful in creating long-lasting products.

Applications in Infrastructure

The potential of bio-fabrication is not limited to fashion. It has also opened new possibilities in infrastructure. Self-healing materials can be used in buildings, roads, and bridges. Over time, these structures often suffer from wear and tear. Cracks can develop, leading to costly repairs.

With self-healing materials, cracks can be automatically repaired without the need for manual intervention. This not only reduces repair costs but also extends the life of infrastructure. The use of bio-fabrication in construction could result in buildings and roads that require less maintenance, saving both time and money.

For example, scientists have developed bio-concrete. This type of concrete contains bacteria that produce limestone when exposed to water. If a crack forms in the concrete, the bacteria activate and seal the crack. This innovation could revolutionize the construction industry by providing a more sustainable and cost-effective solution.

Bio-Fabrication in Fashion

The fashion industry has a huge environmental impact. From production to disposal, clothing creates a lot of waste. The Fashion Revolution advocates for more sustainable practices in the fashion world. Bio-fabrication offers a way to create fabrics that are not only eco-friendly but also self-healing.

Designers are now experimenting with fabrics made from living organisms. These fabrics can repair themselves when damaged. For example, a piece of clothing made from bio-fabricated materials could repair small tears or holes without needing to be replaced. This could drastically reduce the amount of clothing waste that ends up in landfills. Linkhouse

In addition to being self-healing, these materials can also be biodegradable. This means that when the product reaches the end of its life, it can break down naturally, without harming the environment. The combination of self-healing and biodegradability makes bio-fabrication a promising solution for the future of fashion.

The Future of Bio-Fabrication

The future of bio-fabrication is exciting. As technology advances, scientists are finding new ways to create even more sophisticated materials. These materials will not only be self-healing but could also have additional properties. For example, they may be able to change color, shape, or texture in response to environmental conditions.

As bio-fabrication becomes more widespread, it could transform many industries. We could see the creation of buildings that heal themselves, clothes that last longer, and products that require fewer resources. The use of living materials could also help address global challenges like climate change and resource depletion.

The possibilities are endless. With bio-fabrication, we can create a more sustainable and efficient future. It allows us to rethink how we design, produce, and use materials. The self-healing properties of bio-fabricated materials could play a crucial role in reducing waste and extending the life of products.

Challenges and Limitations

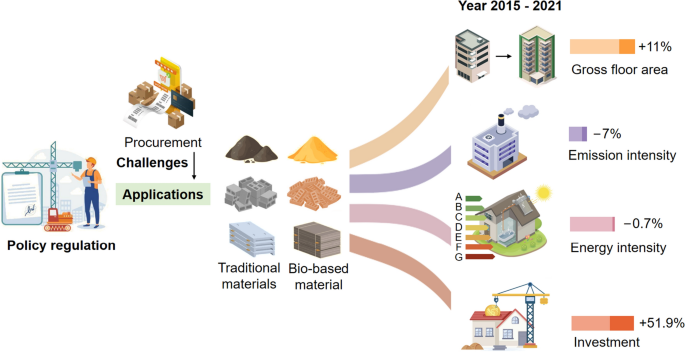

While the potential of bio-fabrication is vast, there are still challenges to overcome. One of the main challenges is scalability. Producing large quantities of living materials in a cost-effective way is still a hurdle. The technology is still in its early stages, and it will take time before it is widely available.

Another challenge is the integration of bio-fabricated materials into existing systems. For example, in the construction industry, there may be resistance to using new materials. Builders and engineers are used to traditional materials, and it may take time for them to trust the reliability of self-healing products.

Finally, there are concerns about the environmental impact of using living organisms in production. While bio-fabrication is more sustainable than traditional methods, it is important to ensure that the processes involved do not create unintended negative effects on the environment.

Conclusion

Bio-fabrication is an exciting field that holds great promise for the future. It is enabling the creation of self-healing products and infrastructure that could revolutionize industries. From fashion to construction, living materials are paving the way for a more sustainable and efficient future. While there are challenges to overcome, the potential of bio-fabrication is vast. As the technology continues to evolve, it could play a key role in creating a world where products and infrastructure last longer, waste is reduced, and resources are used more efficiently.

Stay in touch to get more updates & news on USA Techmagazine!